Experiment Design Analysis to Minimize Variability of

Injection Molded Precision Plastic Parts

January 2020 - May 2020

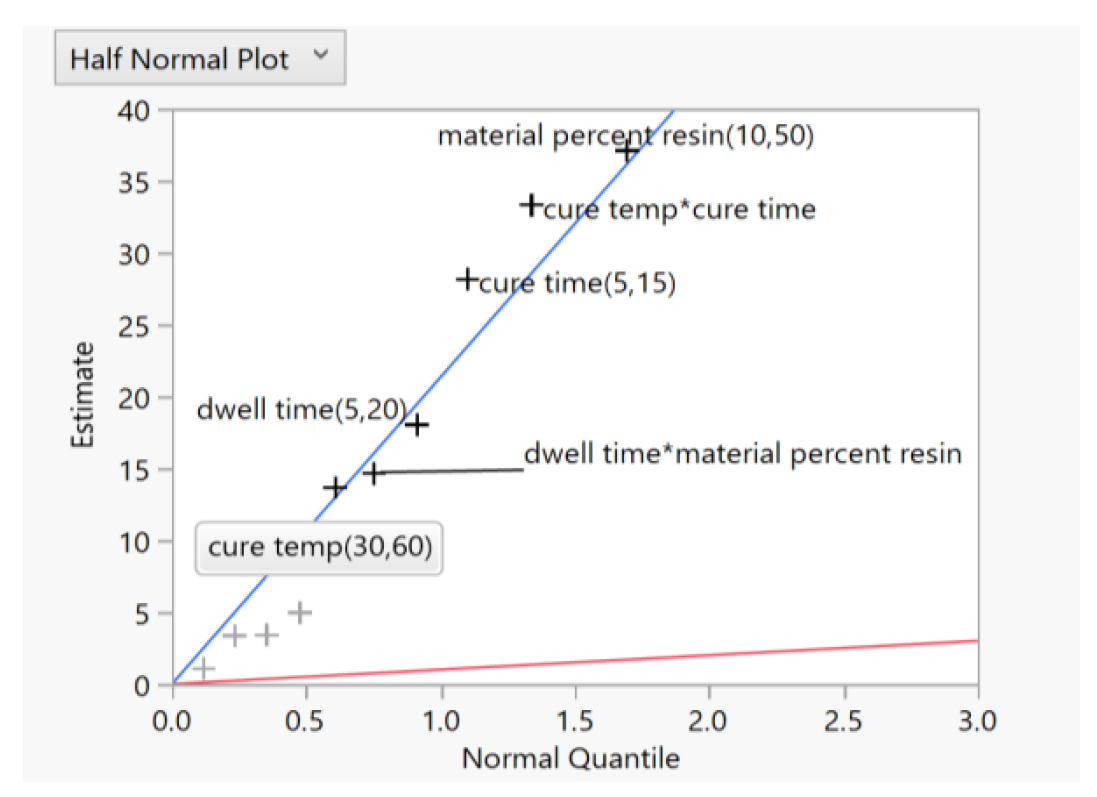

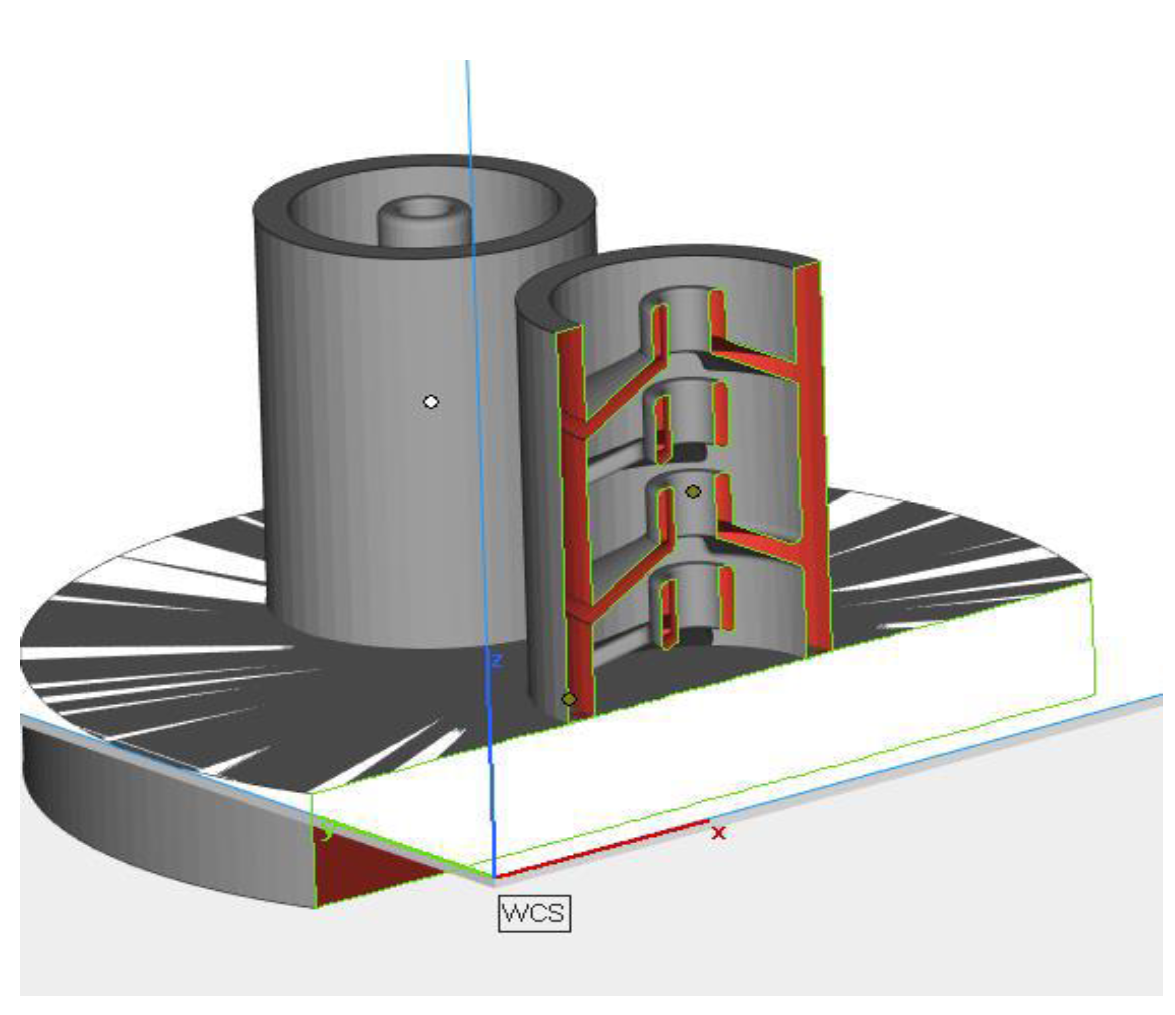

The project required the team to work with a local manufacturer who makes

injection

molded precision

plastic parts to

identify factors in the process responsible for variability in the part. The

experiments were

strictly

constrained to 16 process runs per batch with a maximum of 100 runs.

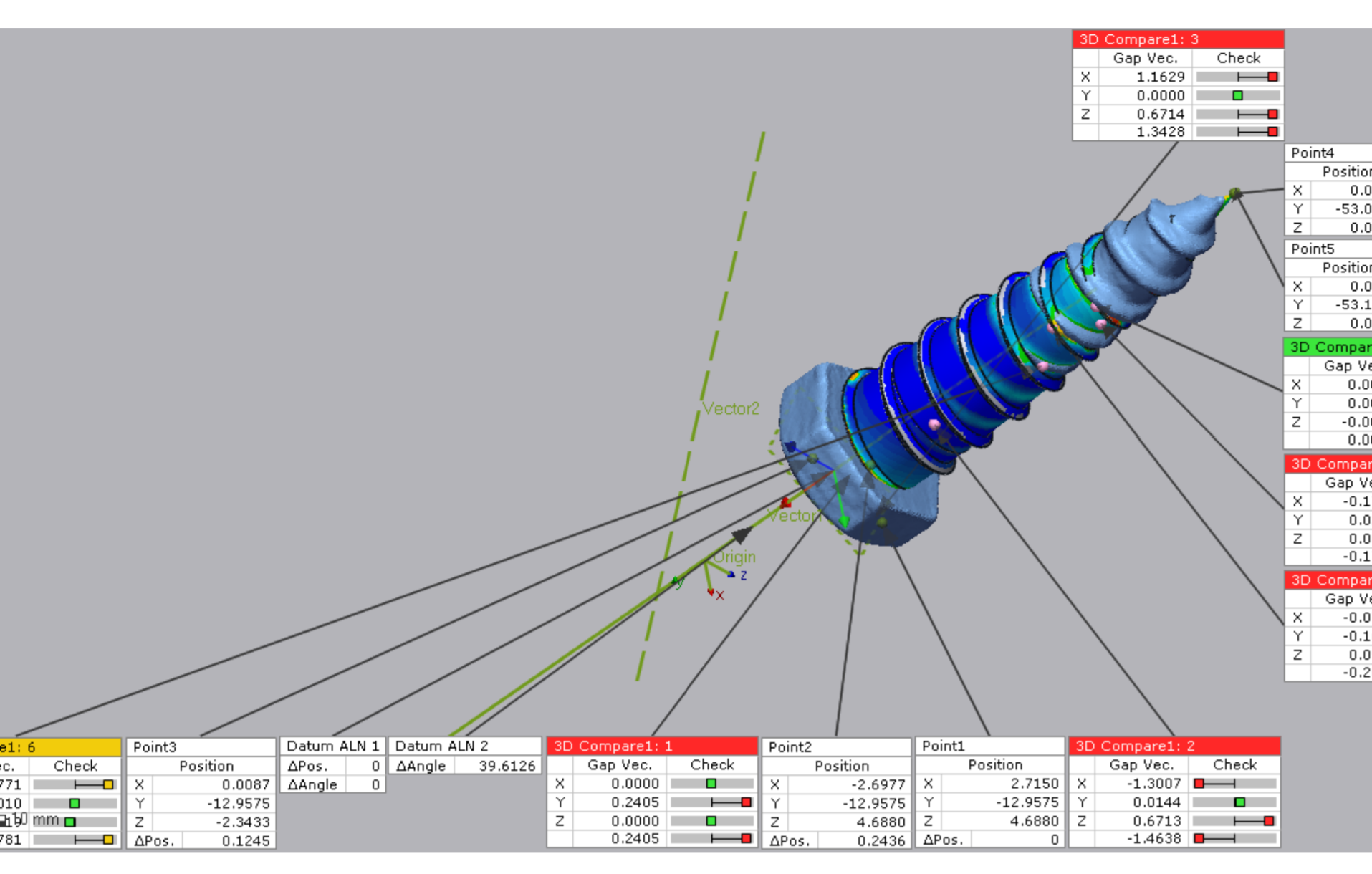

We started

with initial

screening experimental design and ended up optimizing the process

with

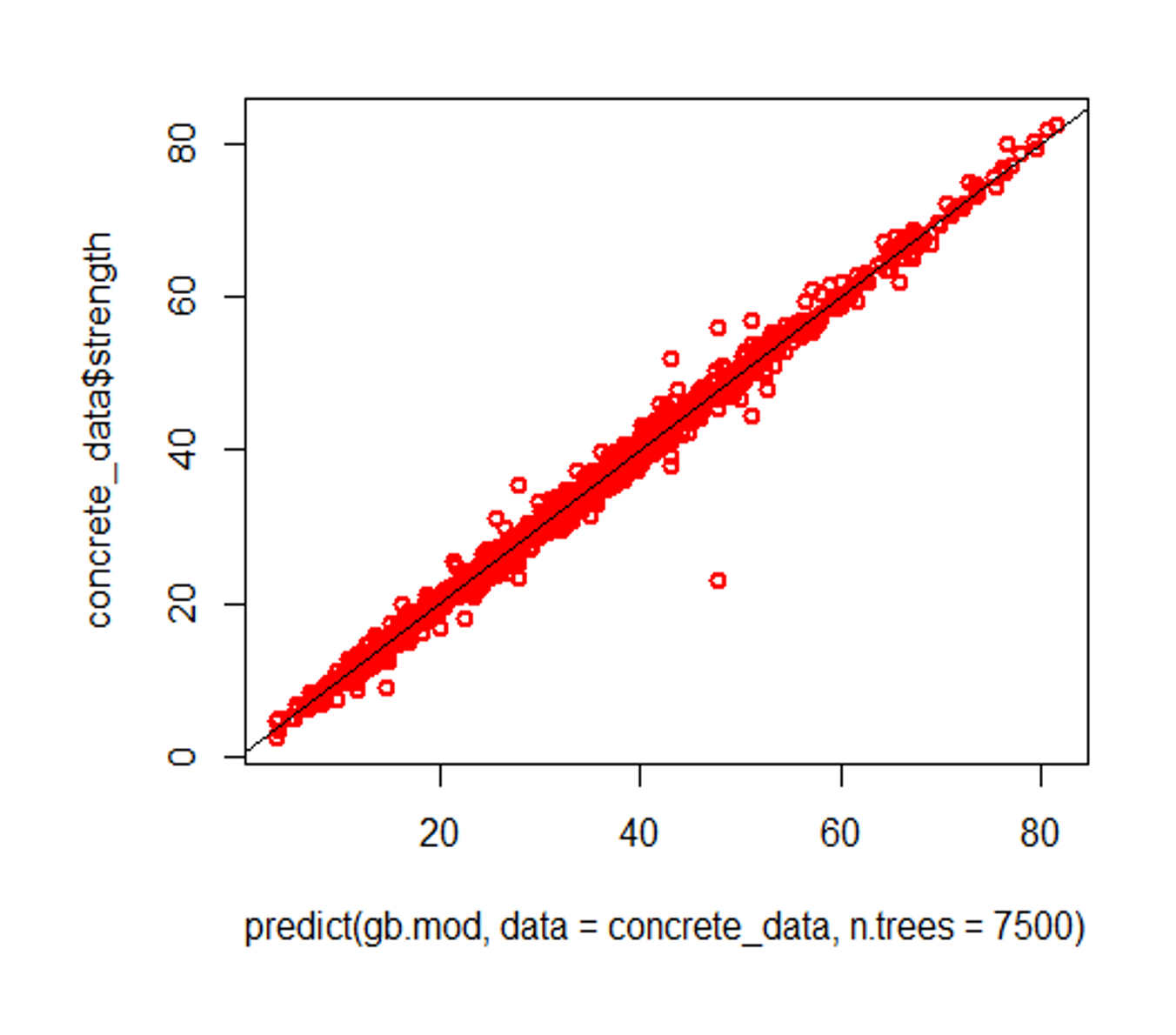

response surfaces and central composite design. We also

developed predictive statistical model based on previous injection

molding

operation data to predict the

response of the process when selecting different combination of process parameters.

JMP • Design of Experiments (DOE) • Statistics • Injection Molding • Process Improvement